Diagnostic Arthroscopy

Equipment For Diagnostic Arthroscopy As mentioned in the first chapter, Diagnostic Arthroscopy requires Arthroscope, Light Source and fluid medium to keep the joint distended during examination. Also, though not a basic requirement, video/camera system has become a necessity. So we include even the video system under this chapter. The final thing that still needs to be added here is a probe that is used to feel/palpate the joint for effective study of the tissues involved.

Arthroscope Set Arthroscope set consists of Arthroscope, Cannula and Obturator and/or Trocar. As mentioned in the first chapter, Arthroscope is a telescope that is used to look inside the joints of body without actually opening them. Arthroscope is made up of three distinct parts. The first part is the eye-piece, second is the shaft and the third is the tip. Eye-piece is the part through which a surgeon views the interiors of the joint, shaft, the longest part of the Scope, has a rod-like appearance and performs the function of transmitting and focussing the image on the eye-piece. The last part of the Scope, tip, performs the most essential function of gathering the image from inside the joint, or to put it more technically, it is the tip that gathers the light reflected from anatomy and focuses it onto the transmitting medium inside the shaft of the scope. Apart from this, the modern day scopes are manufactured so as to accommodate transmission of light from the source to the joint. This is accomplished by making the scope in concentric geometry. That is, the scopes are made like one cylinder over another cylinder. The space in between the outer and inner cylinder is occupied by fibres that carry the light. At the tip, there is a window from where the light is thrown onto the anatomy. The light reflected from the anatomy is collected by the tip of the scope and passed onto shaft for transmission of image to the eye-piece through the inner cylinder. It is obvious that the scope is made up of only optic components; components that handle only light and information contained in that light. There is no electronics involved.

Tip of Arthroscope The tip, as mentioned earlier, is the part of the scope that is completely inside the joint during Arthroscopy. It can be made of any material that can transmit and focus the image onto the components within the shaft. Besides being able to transmit and focus light, the tip material also has to be hard enough to resist scratches from accidental brushing against the bones or any other hard instruments that are constantly inside the joint for surgical purposes. The hardest material that is used as a material for coating the tip is Sapphire. It should be appreciated that Sapphire is the best material for getting distortion-free transmission and focusing as well as hardest for maximum scratch resistance. Obviously, there is a price for better material and in this case it is the cost of the material. Thus, broadly speaking, Sapphire tipped scopes are the best but more expensive than the ordinary ones. The tip of the Arthroscope is available in different angles with the long axis of scope. These different angles are 0deg, 30deg and 70deg. This tip angle defines the direction from which the image will be picked up. Thus, a 0deg scope will pick up image from the area straight in front of its tip. A 30deg scope, on the other hand, will pick up the image whose centre is at 30deg from the long axis of the scope which is also the direction of vision for the surgeon. Similarly, a 70deg scope looks at 70deg to the direction of vision.

Shaft of Arthroscope

The shaft consists of number of lenses arranged longitudinally with spacers in between them. It should be noted that it is not one long lens buts a series on lenses. The first question that comes to mind is why do we need a long shaft and the second one is if we do need a long shaft, why don’t we have one long lens inside it? The shaft has to be long so as to enable the tip to be inside the joint while the eye-piece is sufficiently outside the body for the surgeon to see through it. Typically a 4mm arthroscope is available in lengths of 160mm to 175mm. The answer to second question is that one long lens is required because lens has a very peculiar feature that the longer it is, the greater is its weight and more expensive it is. Thus, in order to make the scope economically viable to sell and also easy to maneuver, we need a series of lenses. These lenses placed longitudinally are separated by spacer blocks that prevent the lenses from banging into each other and at the same time maintain the optical integrity. This combination of lenses and spacers in longitudinal fashion is called Rod Lens Technology. This technology enables the transmission and focussing of image onto the eye-piece satisfactorily at minimum possible cost. Arthroscopes are available in varying shaft diameters. For big joints like knee and shoulder, Arthroscopes with shaft diameter of 4mm are used whereas for small joints like wrist and ankle, 2.7mm and 1.9mm shaft diameters are used. Smaller joints can accommodate smaller diameters and hence the variation in shaft specifications. Also note that the variation in diameter brings about difference in Field of View (FOV). Field of view is defined as the angle, within which the scope can receive light from an object. For any given endoscope, the FOV is constant. Typically, for a 4mm scope, the FOV is of around 110 – 120deg for different makes.

Eye-Piece of Arthroscope

Eye-piece is the proximal end of the Arthroscope that offers the final image to the surgeon or camera, as the case may be. This end is called Eye-piece because the surgeon places his/her eye in front of it to view the image. Hence, such a scope with eye-piece is called as Direct-View Arthroscope. There are other types of scopes that can be connected directly to the camera head of video system. These scopes that come with video sub-assembly are termed as Video Arthroscopes. The eye-piece or the video sub-assembly contains an ocular lens inside it through which the image is actually viewed. The eye-piece also has a post on it that attaches to the light source system components. The light that is generated by the light source is passed through this Light Post which connects to fibre optic strands which run parallel to the long axis of scope. These strands transmit light and through it onto the object of desire. This light post also performs a secondary function of helping the surgeon find his orientation inside the joint. This is because of the fact that the light post is always opposite to/on the same side of the direction of view. The most commonly used scopes have light post on the opposite side of direction of view. Thus, a surgeon only has to look at the direction of light post and he/she can understand that he/she is looking on its opposite side. This helps in orienting himself/herself inside the joint. Note that this orientation is never an issue if 0deg scope is used. For this reason, 0deg scope is very popular among beginners. A 30deg/70deg scope offers much more view just by rotating whereas, with a 0deg scope the surgeon has to point his/her scope directly towards the anatomy of interest. The Direct-View Arthroscope can be used even when performing Arthroscopy with the help of video system. This is possible because the eye-piece of the direct-view scope can be coupled to camera head using special couplers that make it possible. These couplers are made so as to fit around the eye-piece on one end and to the camera head on the other. These couplers are of two types depending upon which type of camera head they attach to. That means, the couplers have either C-mount screw thread or V-mount screw thread depending upon the type of camera head. Also, the couplers can be focussed so that the surgeons can make fine adjustments to best view the image. Technically, endoscopes have depth focus that ranges from zero to infinity but actually the focus changes as the scope is moved away or closer to the anatomy. While viewing directly, surgeon’s eye makes fine adjustments to maintain clarity in spite of changes in distance between the object and tip. When coupled through couplers, it is done by focussing ring provided on the coupler. In case of Video Arthroscopes, the video sub-assembly carries a focus ring on itself. Endocouplers are commonly available in fixed focal lengths of 25mm and 35mm. Apart of all the features discussed above, arthroscopes are also available in different types based on the cleaning method they employ. It should be noted that the above-described scopes cannot be autoclaved because of the simple reason that at high temperatures, the adhesive binding the lenses and spacers with the shaft melts and this makes the alignment of the scope faulty. It should be obvious by now that perfect image transmission is a result of perfect alignment of lenses inside the shaft. Any disturbance in alignment causes the image to deteriorate for slightly bad to completely black. To enable autoclaving of scopes, special technique is used whereby the glass of lens and metal of scope are welded together. This welding can withstand high temperatures of autoclave. Also, the tips of autoclavable scopes are Sapphire tipped to make it more rugged. As is evident, Arthroscopes can be classified in many different ways. They can be classified based on diameter of the shaft, direction of view, method of viewing, length of the shaft and even on the basis of the sterilisation method used for its cleaning. Thus, it becomes obvious that it is not possible to identify any Arthroscope based on only one particular dimension. Typically, an Arthroscope is referred as 4mm, 30deg, Direct-View, Non-Autoclavable Arthroscope. Note that first figure specifies the diameter of shaft while second figure specifies the direction of view. Normally, the length of shaft and FOV are not specified to identify the scope but are mentioned as technical specifications of the scope.

Cannula & Obturator

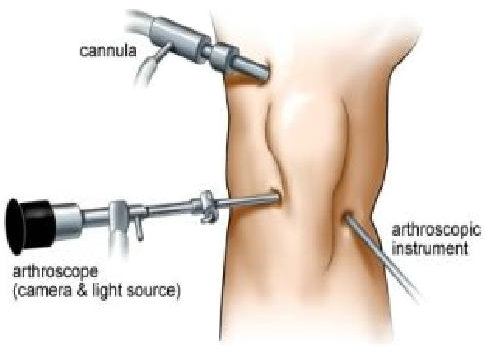

Arthroscope, or for that matter any endoscope, is a delicate device. It needs to be protected against all damaging forces that it might encounter. Precisely for this reason, the Arthroscope should not be inserted through small incisions directly. To enable the entry of scope without damaging, it is inserted inside a Cannula. Cannula is a hollow, tube that can accommodate the scope inside it. At the start of procedures, a small incision of 2-3mm is made in the skin and then this incision is deepened to reach the interiors of the capsule using combination of cannula and obturator/trocar. Obturator/Trocar are solid rods with blunt/sharp tip respectively. Generally, obturator/trocar are slightly thicker in diameter than the Arthroscope. Either obturator/trocar is inserted in the cannula and this assembly is pushed through the shallow incision in skin to pierce the muscles, other soft tissue and finally the capsule. Once the assembly has reached and is communicating with the joint space, obturator/trocar is disengaged from the cannula and withdrawn, leaving the cannula in place. Now, the scope is inserted in place of obturator and the procedure is carried out. In the earlier years, trocar was preferred because of the ease it offers while piercing the joint. Over the years, though, use of trocar is avoided and an obturator is used instead. The explanation for this shift is that the sharp tip of the trocar causes much more damage to the soft tissue while piercing than the blunt tip of obturator. In addition to protection of scope, the cannula also performs another vital function and this is to provide irrigation. This irrigation is nothing but the fluid that distends the joint during surgical procedure and also helps clean up the debris. It washes the joint. Cannula allows the inflow/outflow of fluids from the joint. Cannula/Sheath (as it is commonly called among surgeons) comes with built-in valves. These valves provide for the attachment of tubing for irrigation. The irrigation fluid flows in the space that is present in between the inner wall of cannula and the outer wall of scope.

ENDOSYS Equipment for Arthroscope Set

Endosys has a wide range of Arthroscopes alongwith Cannulae and Trocars. Under the brand name of Nixtronics, ENDOSYS Arthroscopes and Cannulae are widely popular and command a premium in the market. The entire range of Arthroscopes can be seen in our Products Catalogue. Broadly speaking, we have scopes in 4mm, 2.7mm & 1.9mm with 0deg, 30deg & 70deg direction of view, short & long scopes, with light post opposite to and on the same side as direction of view, autoclavable or non-autoclavable. In India, the most popular scope is a 4mm, 30deg, Non-Autoclavable Direct View Arthroscope. This scope has a working length of 165mm, FOV of 115deg (wide angle scope) and the light post is opposite to the direction of view. All our scopes come with J-lock type of mechanism for attachment of cannula. The plus point of our camera is the brand name Nixtronics that is trusted by all the Arthroscopists worldwide and wide angle view of 115deg. It should be noted that the field of view is 115deg in air. Arthroscopy is done in water (irrigation fluid). Because of refraction phenomenon in water, the FOV falls to 79deg. But, all the competitors also mention only their FOV in air. This figure of 79deg should not be quoted unless asked specifically by surgeons. Our Autoclavable scopes have two features worth mentioning. The first is glass to metal welding for ensured resistance to leakage and second is sapphire coating on distal lens (tip). Also, the Autoclavable scopes come with a Maroon band with ‘Autoclavable’ etched on it. The cannula or sheath that we sell in our basic set is double valve, fully rotatable with fenestrated tip and diameter of 5.8mm. 5.8mm diameter ensures sufficient space for fluid and debris flow, double valve with stopcocks provides for inflow as well as outflow of irrigation fluid and fully rotatable feature prevents the entangling of the two sets of tubing when the surgeon is rotating the scope. Fenestrations are provided at the tip of the cannula to allow the passage of debris of surgery with minimum obstruction. This ensures fast cleaning up of the joint. The accompanying obturator is a 4.5mm conical but blunt tip obturator. Cannula as well as the obturator come with J-lock fitting mechanism. J-lock provides secure coupling to prevent accidental disengagement during Arthroscopy. Besides sheath, other cannulae are also available that are used for the sole purpose of irrigation. They are called as inflow/outflow cannulae and are much shorter in length than the sheath. Though not asked for often, these are very important as they help empty the joint of irrigation fluid on completion of procedure.

Light Source Set

Light Source Set Light Source Set is used for illuminating the interiors of the body. It consists of a control unit and light guide with adapters. The control unit contains a light bulb for light production and its related circuitry. Considering its use, the best option would be to use sun light as it is the brightest of all lights. Any light’s brightness is expressed in its whiteness. In its perfect whiteness, the sun light enables us to view the exact colours of different objects that we see. This holds good for Arthroscopy too where it is desirable to view the colours as they really are. Each and every colour is characterised by a temperature associated with it. Sun light has colour temperature of 6300 to 6700deg Kelvin (K). Thus the colour whose temperature is close to 6300deg K is best for our illumination purposes. On the face of it, it may appear that light source should not contain anything but a light bulb and a means to carry the emitted light to the scope’s light post. But the modern day light source has much more than this. Today’s light source incorporates, besides light bulb and connector for light guide, a fan and a series of lenses before the connector. The fan is required to cool the bulb when in operation. This is avoid the over-heating of bulb and light source as a whole because, when over-heated, the light source may stop functioning. In fact, modern light sources ensure that the light does not come on if the fan isn’t working. Incidentally, the presence of fan makes light source the heaviest equipment used in Arthroscopy. The series of lenses is required to focus all the generated light from the connector into the light guide to prevent any leakage of light. Over and above this, most of the units come with adapters to accept light guides from different manufacturers.

Different Types Of Light Sources Light can be generated through various sources with each source and its product having relative merits and demerits. Today, there are three types of sources that are commercially available. In ascending order of their merits, the three types of sources are, Halogen light source, Metal Halide light source and Xenon light source. All three sources employ different methods of light production. Halogen light source emits light on heating of filament, Metal Halide light source produces light when arc discharge ignites gaseous salt whereas Xenon light source produces light when the arc discharge ignites the gas. Though this difference in the technology of light production is immaterial to selling the instrument, it is essential for a sales person to know of the different technologies available so that, if the need arises, the sales person can discuss the issue with the concerned surgeon. All the different types of light sources come with a knob to vary the brightness of bulb. Apart from the technology they use, these light sources also differ in their features. Halogen light has a temperature of 3200deg K giving it a yellowish cast, Metal halide light has a temperature of 5600deg K rendering it a blue-white cast whereas the Xenon light has a temperature in the range of 5800 to 6000deg K making it pure white in colour. This obviously translates in better colour visualisation which means ease in surgery. Xenon light source also remains bright over its entire life of minimum 500 hrs whereas Metal Halide and Halogen light sources gradually lose their brightness over their life of 250Hrs. approximately. This means that after 500 hrs, Xenon light source can stop anytime; even in the midst of a procedure causing loss of picture. To avoid this, the hospital staff has to be advised to keep one replacement bulb always in the operation theatre. There is no warm-up/cool-down time in Xenon light source whereas Metal Halide light source suffers for 30sec for warm-up and 5min for cool-down. Finally, Xenon light source is the most expensive of the lot followed by Metal Halide and then by Halogen light source.

Light Guides & Adapters The light that is emitted from either of the light sources, needs to be carried to the light post of the scope so that it can be passed inside the body to illuminate it. This carriage of light form the source to scope has to be with minimum loss of light energy so as to maximise the useful life of the bulb. Loss of light can occur on two fronts; due to loss in open environment and due to loss of energy on account of reflections inside the carrying medium. To prevent loss in open environment at the connector, lenses are built-in inside the control unit to focus all the light at the required exit point, the point that connects with the light guide. To prevent both the kinds of losses, modern light sources come with light guides that are specifically designed to transmit maximum and lose minimum light. This purpose of maximum transmission is achieved using either the liquid light cable or the fibre optic cable. The liquid light cable is single tube filled with liquid that allows maximum transmission of light. This type of light guide is best as it gives the brightest light. On the other hand, fibre optic cable is made up of thousands of fibre optic strands. Fibre optic strands use the principle of total internal reflection that make them ideal for minimum loss and maximum transmission uses. The number of strands within one cable vary with the diameter of cable. Thicker the cable, more the number of strands and brighter is the light. Although fibre optic technology gives maximum transmission, it still isn’t as efficient as liquid light cables. Due to this, the light is not as bright as its liquid counterpart. Also, liquid light cables are more resilient against bending as compared to fibre optic cables whose strands are very fragile and may break due to acute bending. But, liquid light cables are much more expensive than fibre optic cables. Thus, most of the manufacturers supply fibre optic cables by default, unless otherwise stated. To attach these fibre optic/liquid light cables to the light source and the scope, adapters are provided. These adapters are different for different light sources and scopes. Each scope and light source has its own distinctive attachment mechanism. For the light source to be universal, different connectors are made available by all the companies dealing in light sources. Even the receptacles on the control panel of light source are made so that they can be selected for particular make of cable and scope.

ENDOSYS Equipment For Light Source Set

Endosys has only Xenon light sources in its portfolio. We have Xenon light sources of varying wattage for different applications. A 100W Xenon light source is enough for Arthroscopy applications. For other applications we have 180W Xenon light source called Xenon XL. Recently, Endosys has also released a 300W Xenon light source which suffices the needs of all the surgeons; be it an Arthroscopist, General Surgeon or Gynaecologist. With high wattage, it is possible to use this light source in any of the applications The most popular model in India is the 100W Xenon light source . This light source comes with a guaranteed life of minimum 500hrs per lamp module. Lamp module is the assembly that incorporates the Xenon bulb. Our assembly is very easy for users to replace. The old assembly can be removed through the window provided on the side of the control unit and the new just slides into place. Thus, if the hospital keeps a spare assembly in stock, there is no down time even in case of expiry of the lamp. Our light source also provides continuous variation in light intensity through rotatable knob. It incorporates only manual mode of operation hence it has to be used with a camera that functions in auto mode for image quality control. It is also compatible with cables of most of the existing players in the market. We provide a 5mm thick fibre optic cable with 2 adapters. If the scope as well as the Source are of Nixtronics make, the applicable adapters are Cat no. 2146 and 2147. It should be noted that the attachments for Wolf are also the same. If the customer is buying a local Halogen light source, the attachments are of Storz type.

Camera System

Camera System As discussed earlier, camera system is not required but is considered essential to reduce surgeon fatigue and complications arising out of it. Before going into the camera systems in ENDOSYS portfolio, it is better to understand a few terms that are common to video technology as a whole. It is essential to know and understand the technology as almost all the video systems are differentiated on the basis of its image quality which is a function of its specifications.

Video Technology All the video imaging systems use the principle of conversion of light energy into electrical energy so that this electrical signal can be processed to project it onto a TV monitor where it is reconverted into light signal. It should be understood that human eyes can visualise only light images. They cannot view electric signals. Conversion of light energy into electrical energy is required so that the image can be processed to make it sharp and better to view. The device that helps conversion of one form of energy into other is called a Transducer. A transducer converts one form of energy into other but without disturbing the information coded in the energy. Thus, when light is converted into electrical energy, the information coded in it, i.e. image, is still preserved. It is now stored in form of electric signal. This signal can be Analog or Digital in nature. In case of analog signal, the information is stored in wave forms whereas in case of digital signal, it is in 0’s and 1’s. Digital processing and/or digital signals have much more clarity and accuracy than their analog counterparts. When the conversion is made, there are different waveforms that contain respective information regarding the place from which the original light came. When the electric signal is processed and reconverted into light energy, the points that are illuminated on the TV screen are in accordance with the original locations. This enables us to get the original image back. One such transducer that converts light into electric signal is Charged Coupled Device (CCD). Commonly known as ‘Chip’, the CCD is rectangular in shape and wafer-thin in thickness. It is made up of Silicon. Some parts of this rectangular chip are activated while others are not. These activated parts of Silicon are called as ‘Pixels’. It is pixels that do the actual conversion. The ‘Streets’ among the pixels are inactivated silicon which conduct the converted electrical signal. ‘Activation’ of Silicon is done by doping it with some other material that is sensitive to light. When exposed to light, the activated Silicon gives rise to a electric charge that is proportional to the intensity of light that it has encountered. Different pixels on the same chip encounter different intensity of light. This is because different matter reflects different amount of light which is specific to that matter. The light reflected form different matter spreads in all directions. The pixels falling in line with the reflected light receive it and convert it to proportional electrical signal. Owing to this phenomenon, it is also possible to assign colours to different matter being imaged. It should be noted that the light that falls on ‘streets’ is wasted. The inactivated silicon does not respond to the light signal. This means that to get a better picture, either the entire chip should be full of active pixels or the light has to be stronger. One way is to use a stronger light source. The other option of having the entire chip activated is not feasible because the electric potential generated by active pixels have to be conducted to the control unit for processing. In absence of ‘streets’ it is not possible to conduct the signal without losing the information regarding location of light and hence the image. To overcome this problem, modern chips come with in-built micro-lenses that focus more light onto the pixels. Each and every pixel is enclosed by a micro-lens that collects the light falling on the periphery of pixel or onto the streets and focuses it onto the pixel. This does not eliminate the wastage of light but it reduces it to a great extent. At the same time it is also true that the greater the number of pixels, the better will be the image. The number of pixels on a chip can be increased by two ways: one is by increasing the size of the chip and other is by increasing the density of pixels on the same chip. Both the options have limitations. The overall size of the chip is limited by the desired size of camera head and the density is limited by need of streets on the chip. The size of the chip can also be not increased because of its cost factor and also that it becomes more and more fragile with increase in size. Dimensions of chip are commonly referred to in terms of its diagonal. Chip is always rectangular in shape and its diagonal is used to denote its size. Thus, when we say that a camera has chip, we mean that the diagonal of its chip is long. The longer the diagonal, the more the number of its pixels. This chip is contained in ‘Camera Head’. Thus, camera head is the most important component of the camera system. The housing of camera head has threads that screw the coupler/video arthroscope in place. Commercially available camera heads are of different sizes, i.e. C-mount and V-mount. C-mount camera head is 1†in diameter while V-mount camera head is (9/16)â€. The image that is picked up by the scope is transmitted to the chip inside the camera head which converts it into the electric signal. This transmission of image from scope to the chip or camera head is done differently with video arthroscopes and direct-view arthroscopes. Video arthroscopes come with in-built threading and focussing controls. The Video arthroscope can just be screwed to the camera head. In case of a direct-view arthroscope, there is no threading on the scope’s eye-piece. To attach this to the camera head, special optical devices know as Couplers are used. Couplers are simple optic devices that fix on one end to the scope and on the other to the camera head. Besides this, they also have focussing attachment onto them that helps the surgeon focus on different depths and hence different parts of the body without moving the scope. To attach to different diameter camera heads, couplers are also available in C-mount and V-mount diameters. Besides this, the couplers are also available in different Focal Lengths. The light that is transmitted from the coupler onto the chip is converted into light signal by pixels on the chip and passed onto the adjoining streets. All the streets of chip combine into one single cable that originates from the other end of head and transfers the signals to camera control unit where the signal is processed. Processing of signal essentially means decoding the signal and making it suitable for acceptance by TV monitor. This decoding means reassembling all the information contained in the signal so that it can be projected onto the TV monitor. This processing can be done using either analog or digital processes. As mentioned earlier, digital processing of the signal always produces better image that analog processing. This is because digital processing is more precise than analog processing. It should be understood that when one refers to a camera as a digital camera, it could be that the signal is converted into digital form or the processing is done digitally or both. On processing the signal is made of amplitude that can be sensed by the TV monitor. This amplified signal is then transmitted to the TV monitor’s video input. Transmission of signal from camera to monitor is done in various formats. These video formats are as listed below:

BNC / Composite Video Format This is the most basic type of video format used commercially. In this format, both the signals, i.e. Luminance and Chrominance are transmitted on a single cable. It is basically a co-axial cable. The centre-most wire is the line that conducts video signal. It is surrounded by an insulating material. On this insulating material is wound the ground wire in form of a mesh. Finally, this ground wire is covered by the outermost insulation. It is also called Composite Video format because the video signal is composite in nature, i.e. both the signals are conducted on the same single wire. Most economic format, BNC is also the most reliable because of its sturdy design. But the BNC format also has its own disadvantages. The biggest disadvantage of this format stems from the fact that a single wire transmits both the signals. The same wire conducting both the signals causes lots of interference which leads to loss in image quality.

Y/C / S-Video / S-VHS Format

To overcome the drawbacks of Composite video format, the two signals are conducted on two different wires in this format. The cross section of a Y/C cable reveals the it has four wires; one for Chrominance, one for Luminance and two for Ground terminal. This isolation of signals improves the quality of image appreciably. But this format requires a special connector on the monitor to accept this cable. It cannot be connected onto the BNC type of connector. Since the format uses more expensive circuitry and also is for higher quality of image that is not required in ordinary uses of TV monitor, ordinary monitors do not have any provision for accepting this format cable. Specially designed medical grade monitors are available to accept this format besides BNC format.

RGB Format

To overcome the drawbacks of Composite video format, the two signals are conducted on two different wires in this format. The cross section of a Y/C cable reveals the it has four wires; one for Chrominance, one for Luminance and two for Ground terminal. This isolation of signals improves the quality of image appreciably. But this format requires a special connector on the monitor to accept this cable. It cannot be connected onto the BNC type of connector. Since the format uses more expensive circuitry and also is for higher quality of image that is not required in ordinary uses of TV monitor, ordinary monitors do not have any provision for accepting this format cable. Specially designed medical grade monitors are available to accept this format besides BNC format.

Component Video Format

This format consists of R/Y, B/Y and Y signals. Primarily used for appliances such as video printers, this format gives the best quality. In fact, it also uses the same connectors as RGB with a toggle switch to select between the two formats.

Terms In Video Technology

Common Terms Used In Video Technology Besides the technology discussed in above paragraphs, there are few other terms that are used very frequently when talking about or comparing camera systems. It is essential to understand these terms as they are the key points in discussion with surgeons. The terms that we will discuss are:

Electronic Shutter As discussed earlier, all camera systems work on the principle of conversion of light into electric signal. In general terms, more is the illumination, better is the picture. But, too much of illumination also is bad for the image as it tends to shine/bloom in access of illumination. For a evenly illuminated image, we need controlled light. The amount of light that has to be taken in is controlled by a special apparatus called as shutter. Shutters are incorporated in the design of the equipment. Shutters are mechanical or electronic in nature. Mechanism of Mechanical Shutter can be best explained on comparing it with the Iris of our eyes. When we come out of a dark surrounding into sunlight, our eyes contract instinctively. Alongwith this, the Iris, that is the door of sensing aperture, also decreases its open area to restrict the amount of light that enters the eye-ball. This is to avoid the blooming and getting a coherent image that falls in the line of vision. Similarly, the camera also has an aperture through which the light enters and encounters the chip. This aperture’s opening/closing is controlled by the mechanical shutter. This mechanical shutter has moving parts. Obviously, this is prone to damage. Also, the response to light changes is very slow. Modern day cameras use shutters that control the incoming amount of light electronically. This is achieved by activating the pixels on chip for a limited amount of time. This time of activation is dependant upon the intensity of incoming light. By keeping the activation of pixels only for a limited amount of time in one cycle, we can control the incoming light so as to get a picture with perfect brightness. This control is done automatically. Thus, when we say that a camera is working in auto mode, we mean that shutter control is automatic. Cameras can be used in manual mode also, but this is done only when the light source is in auto mode. It is important to note that when the light source is functioning is automatic mode, the camera has to be in manual mode and when the light source is in manual mode, the camera has to be in auto mode. When the light source is in manual mode and camera is in auto mode, there is no need for any specific arrangement. The light source emits light as programmed manually and the camera, in turn, senses the intensity of reflected light and adjusts automatically using its electronic shutter control. On the other hand, when light source is in auto mode and the camera is in manual mode, it is the light source that has to adjust the emission of light so as to get a quality image. The camera does not adjust for light intensity. In order to facilitate the control on the intensity of emitted light, the light source has to be given a feedback from the camera. This feedback ‘tells’ the light source about the intensity requirements. The light source, that is in auto mode, then adjusts its output so as to get a quality image.

Signal To Noise Ratio Signal to noise ratio that tells one how immune the system is to random interference. Any electric signal, however technically advanced, always picks up some interfering signal. This interference signal causes disturbance in the original output of the system. Note that the word output is used in place of image because interference is a phenomenon that is not only restricted to the camera system but is associated with all electric circuits. If the interference is very high the output can be distorted beyond recognition. Because of this reason it assumes great importance in deciding the quality of the output of the system and hence, the system itself. This interference, commonly referred to as Noise, is expressed in all the manuals of any electric product. It is expressed in terms of its proportion in relation with the actual wanted signal. Electric signals are expressed in a unit called decibels (dB). Thus, noise also being a electric signal (unwanted), is also expressed in the same unit. An accepted form of expressing the proportion of noise in relation with signal is Signal to Noise Ratio (SNR). Simply put, it says for how much part of wanted signal, there is one part of noise. Calculated simply by putting total signal decibels in the numerator’s place and total noise in the denominator’s place, this ratio provides adequate insight into the quality of output. SNR does not have any unit because both the numerator and denominator have the same unit. It should be obvious that higher the SNR, better is the system. This feature of the system gets lots of focus from sales personnel of all the different companies. This specification is a function of design of the circuitry and hence solely in the hands of the manufacturer. Better design and use of better components ensures minimum noise. It should be noted that no system can ever have nil noise.

Resolution

This specification is another indicator of the quality of image produced by a camera system. Resolution refers to the degree of ability of a system to resolve the image. In other words, this refers to how clear an image can a system produce. The clarity of an image is a function of how many lines it is broken into. This breaking down of image into lines of information decides the resolution of the system. Hence, it becomes evident that more the lines of resolution, more the lines of information and thus more the clarity of image. It should be noted that a camera system has its own resolution whereas TV monitor has its own. The overall resolution of the system is whichever is lesser of the two mentioned above. To process the image, it is split in two different ways, i.e. in horizontal scan lines and in scan vertical lines. The space between adjacent scan lines (horizontal as well as vertical) are filled in by averaging on both the sides. This should make it clear that to obtain the image as it is without much averaging, we have to have a large number of lines and more the lines, lesser the approximation and hence truer the image. Since the chip is of limited size, the lines cannot be infinite. Also, to increase the number of lines, they have to be more densely packed. Constant research is put into increasing the number of lines. But it should be noted that of the two lines, one can be changed by the manufacturer but not the other one. The one that is under manufacturer’s control is vertical lines on horizontal plane (Horizontal Resolution). The Vertical Resolution (horizontal lines on vertical plane) is constant depending upon the transmission system used. There are two types of scanning formats, namely NTSC and PAL. NTSC format is used in western countries and has a fixed horizontal resolution of 525 lines and input voltage of 110V whereas in countries like India, PAL format is used which has a fixed vertical resolution of 625 lines and input voltage of 220V. Horizontal resolution is a function of design of the camera system and varies with each and every manufacturer. All companies strive to have more number of resolution lines in their system as it speaks volumes about their image quality.

Sensitivity To Light (Lux)

As understood, the intensity of light is essential for a good image. But, producing high intensity light is very expensive and hence it is desirable to have highly sensitive camera systems that can pick up the image with minimum illumination. Light sensitivity is measured in units called Lux. Thus, to put it in other words, we desire a camera system that produces a good image even with minimum-Lux light. Thus, we actually desire more sensitive camera systems. The minimum illumination required is a function again of the design of camera and is controllable by the manufacturer. A noteworthy issue that deserves a mention here is that comparison of sensitivities of camera systems cannot be done purely on Lux factor. It is equally important to compare Lux from a specific constant distance without which the figures hold no good. Thus, sensitivity should be expressed in Lux/Foot Candle where foot candle implies when a candle is placed at a distance of 1 foot from the chip. This distance may vary but has to be held constant when comparing two different systems. Thus, when one says that his/her camera has light sensitivity of 1.5 Lux while someone else’s has 2 Lux and hence his/her camera is more sensitive is a misguiding statement. On the other hand, if he/she says that the sensitivity of his/her camera is 1.5 Lux at 1 Foot Candle while that of the competitor is 2 Lux at 1 Foot Candle and hence his/her camera is more sensitive, then the statement is correct. Taken in toto, all the above four specifications in a camera system together give an indication of the overall quality of the camera system.

White Setting

White setting is the procedure by which the camera is ‘taught’ what is white colour. Once he camera ‘know’ what white is, it can derive all the other colours from it because white colour is composed of all the seven colours. White setting procedure is very simple and takes hardly any time. All one needs to do is focus the scope with camera attached to it on a white piece of Gauze and press the white set button. In approximately 20sec, the camera gets white set and is ready for operation. This procedure has to be repeated before every procedure to ensure proper colours on the monitor.

ENDOSYS Equipment For Camera System

Endosys offers its Camera System under the brand name of Images. It offers exhaustive range of camera systems ranging right from single chip cameras to three-chip cameras. Even among single chip cameras, we have two different brands that cater to different segments based on price sensitivity. In the higher price bracket, we have TRENDCAM1901 PAL camera system. It is a very recent release with improvisation in features over the previously existing D1 camera system. TRENDCAM1901 PAL has 560 lines Horizontal Resolution and a minimum SNR of 54dB. It packs 900,000 pixels on its single chip that produces exceptionally crisp images. Illumination requirement is of 5 Lux @ F1.4. With these specifications, TRENDCAM1901 is the best camera system in single chip segment. It gives images of quality that is comparable to a 3-chip camera.

Copyright © ReifierSoft 2017. All rights reserved